More and more people are building highly modified Minis, some with engine conversions, others fitting items such as the Mini Spares 8 Port, all these parts can make fitting a speedo cable drastically difficult, and with limited availability of the correct combination of speedometer worm....

Read more

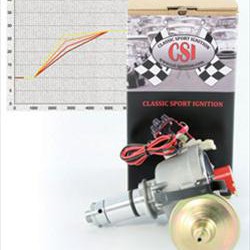

Fitting Minispares electronic dizzys ADU5789MS 998cc 1982 to 1993 A+ ballast type ignition Read more

Fitting Minispares electronic dizzys

GEU930MS,

12G2140MS,

BAU1962MS

1959 to 1982 non ballast type ignition

The red wire should be connected to the positive side of the coil and the black wire to the negative side. The wire that was connected to the points can be taped back to the main harness out of the way. Read more

This large plastic shield was Rovers last attempt to cover the engine electrics on all minis except for MPI cars 1996 on. It might need slight modifications by narrowing for some SPI cars but they have been fitted to many cars without any problems. Read more

We now have a new range of electronic ignition distributors available. Read more

'To solder or not to solder, that is the question'

Despite having spent something in the order of 26 years delving into all things automotive and some 24 of those concentrating a great deal on the Mini, I have never assumed I know it all. In fact I'm very much one of those to support the 'you never stop learning' theory. My latest endeavours to get out racing again have caused me to look at all things connected (sorry - pun) with racecar preparation - the wiring loom being one such item.

I decided to canvas everybody I knew that was involved with electronics and electrics to any degree to see what the latest state of ply was concerning fixing terminals to cables. 'To solder or not to solder, that is the question'. All my previous racecars (last one built about 14 years ago) had all the terminals carefully soldered on. It used to take me ages; taking a remarkably long time to become proficient at it - largely because of the 'not too hot' soldering iron I'd purchased to do the job. Read more

Completing this change successfully, easily and neatly is pretty straightforward on a Mini. The alternator contains the regulator and cut out functions within it’s casing, so makes the regulator box used with a dynamo redundant.

Part No Applications: GEU205, GEU205MS, GEU207, GXE2297

However, it is useful to retain the box itself and it’s connectors. It acts as a terminal box to make the installation neat, avoiding the messy and awkward soldering/taping together bunches of wires. It also maintains a period look, plus makes reversal easy should this be needed in the future.

Disconnect the battery and remove the black regulator box from the car - taking care to make a note of or label each wire removed with it’s original terminal connection. Fit the alternator using the necessary rear support bracket (part no. 12G1053) as the alternator is shorter than the dynamo. The relevant belt (GCB10825) is also needed. Read more

Since the A-Series has such an efficient combustion chamber design, the standard points set-up is perfectly capable of providing sufficient sparks for effective combustion when new. And this is the problem. They require regular servicing to maintain maximum performance. This can be a chore, so is generally neglected. And it doesn't take long before deterioration seriously affects performance. Points bounce is also a problem on high-revving race motors.

Deterioration of the points set-up can be caused by several factors - wear and tear on the dizzy spindle bearings creating 'wobble', electrical erosion of the points, and wear of the points cam heal. All have the same effect - dwell angle alteration. This in turn reduces spark effectiveness. The consequences are a loss in power and economy, poor starting performance, and general poor running.

Read more