It is widely known that when cars have suspension designed for standard road use, shortcomings are exposed when under, erm, “progressive road driving. The situation is even worse under competition conditions where regulations inhibit use of rose jointed suspension. The Mini is no exception. The soft rubber tie rod and bottom arm bushes produce excessive weaving under heavy braking and wandering under fast cornering... Read more

Air, so far hasn’t been subject to privatisation, consumption charges, or tax, so you may well use as much of it as possible. What better way to use it than getting as much of it as possible into your engine – it tends to help power output considerable!

In the first issue of Minitech News we covered our Stage One Kit for the998cc showing showing the power gained by its installation. Part of that kit is Mini Spares’ own alloy inlet manifold. In the second issue we outlined the details of its production and increased flow potential. Read more

A question frequently asked by customers buying new valve guides is what size the guide should be reamed to once fitted. The answer initially is easy, 9/32” (.812”). However, nothing in life is simple.

Correct sizing of the guide is very important. Not only does the guide support the valve, but also helps dissipate heat from the valve – especially important for the exhaust valve. This particular point is even more critical now that hi-grade fuels are no longer available, worsened by many people converting to lead-free fuel. Read more

Every year in America and Canada, Mini enthusiasts get together for a Mini “Convention”. In fact there are two held, due to the copious quality of “surface area” that makes up North America and Canada! One designated Mini Meet West and the other (Surprise surprise) is the Mini Meet East. Each year one of the numerous Mini owners Clubs volunteers to arrange and conduct the meeting at a venue in their area. Read more

Last year at Willow springs, California the gauntlet was thrown down by Mini Mania, USA, to see which was superior. The front wheel drive saloon, or the rear drive sports car.

When these cars were new there were very few organised races for them to compete against each other and the Sprite MK1 or Frogeye as we know it, because of its headlights mounted on the bonnet, only had a 948cc engine while the early Minis only had 848cc or 1275cc of the Cooper “S”. Times have changed and most Frogeyes... Read more

Contents for Minitech News March1992 Read more

This gear system has been specially developed to offer a greater variety of ratios based around a common 30 tooth idler gear. This greatly reduces the cost of changing ratios as a maximum of two other gears are all this is necessary to alter to a required ratio. It is also less costly than changing a crown wheel and pinion.

The fewer teeth on the idler gear, in comparison to other makes, also increases the strength of the gear – minimising failure when used on the more powerful A series engines. The advanced technical design, method of production and stringent individual post manufacturing checks, ensures gear lash is kept to a minimum commensurate with reliability. This reduces the “rattle” associated with straight cut gears by an appreciable amount, making them more civilised for road use.

The following list shows attainable ratios with this system Read more

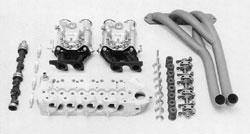

A desire to solve induction installation problems and assist in the choice of induction types for many ‘A’ series applications, led to the production of a new range of Manifolds from Mini Spares, London, to mount on the ubiquitous SU carb of various types and sizes.

Despite numerous manifolds being available from many different sources, there seem to be three times as many problems when... Read more

Development work on the electronic systems disclosed in the first Mini Tech News has been progressing, albeit slowly. Unfortunately we have stumbled on a price problem. Having originally been quoted one price at our original discussions about total market price of the package, we had one test unit produced. Then on asking for price confirmation prior to production we get a MASSIVELY increased price quote! So the heavy discussions begin! We’re still arguing!

Still, in the meantime the prototype was fitted to my road car. My partner in crime on this project and I were gob-smacked when it all worked perfectly first hit of the button. We drove up and down with the lap top plugged in and fiddled with the amount of advance and curve – which was an interesting experience. It was actually possible to tell the performance changes when adding and subtracting degrees... Read more

Research development and production of new and alternative products for the ‘A’ Series goes on unabated at Mini Spares Centre, London. Not only in the never ending quest for more power from the evergreen engine, but also in the components around it to usefully and reliably transmit that power to “terra-firma”.

The past 12 months has seen Mini Spares involved in much research and development in the gearbox department, trying to solve reliability, quality and power transmission problems.

Current standard baulk rings produced in sintered metal are not man enough to deal with the demands of performance usage, in many instances only lasting one race before failure. The main reason is the incompatibility of the material specification with the usage to which it is being put. Basically it is too brittle. Mini Spares competition baulk ring Read more

Warm weather is just around the corner in Britain, so along with winter draws, the roofs will soon be coming off cars all over the country.

Of all the soft top Minis that we have seen, there is none more stunning than the Cabrioni. This conversion, from the Netherlands based company is of the highest standards of quality and workmanship. It is only offered for sale in Europe and Japan at the moment... Read more

Some years ago whilst racing in the National Mini Miglia Championship I came across an odd problem that had me a little puzzled for a while.

I built a new engine ready for the beginning of the season from all new parts except for the block, crank and head casting. I duly ran this in a Snetterton, calling in to visit Peter Baldwin at Marshalls of Cambridge for a final rolling road tune up.

The engine performed faultlessly for 4 races, giving good power and was very smooth, allowing me to use 9,100 rpm on occasions. At the next race meeting I went out to do the practice session, did a few warming up laps, then registered a vibration from the engine. Oil pressure OK, water temperature OK, but it would not pull any rpm and got very rough over 5,500 rpm! Read more

Further to our recent flywheel development for the fast road market comes the latest in the range – a light, steel replacement outer section for the Verto type assembly.

Owners of more modern Mini’s and Metro’s have been bemoaning the fact that they are lumbered with the assembly fitted to the car. The conversion from Verto type to the earlier system realises an unacceptably high financial investment, impairing output of modified engines to add insult to injury! Mini Spares to the rescue once more!

The flywheel is CNC machined from an EN8 steel billet (as are both the other ones) lightened as far as is practical and safe. The overall weight reduction between this and the standard iron item – which is impractical to lighten – is in the order of nearly 4lb. This is of course, reducing the weight exactly where required – from around the outermost “edge” of the flywheel assembly. Read more

Following the great furore experienced by the first generation of four pot alloy calipers, we have not been idle. To meet the demand, greater manufacturing control was needed, necessitating in the production of new moulds. This gave us a chance to further improve the design, and widen the range of fitments to include the 12” and 13” wheeled cars, using the full 8.4” diameter discs for both solid (latest Mini) and vented discs. This means that the Mini Spares caliper will fit:- 10” wheels with the 7½” S disc, machined down 8.4” solid disc, even if a vented disc is the owners choice.

A broad variety of options that minimise outlay to install are possible, as the alloy calipers can be supplied to bolt directly to the swivel hub to cover all these set-ups. There is a direct replacement for the original S/1275GT set up which can also be used on the later disc and the drive flange assembly with only the disc diameter to be reduced. Read more

Have you ever been in that situation where you’ve decided to do something, started it, then a myriad of obstacles suddenly appear making progress snail-slow. Read more

In 1988, a humble 1973 Mini 1000 was minding its own business somewhere in London, when along came a young Mini freak called Jason King, who wanted to change it for ever, and make it famous.

Jason persuaded the owner to take £450 for the car, and then proceeded to throw £12,000 worth of presents at it for the next 3 years. Every minute of Jason’s spare time was spent working on his new car and every minute of his working time was spent looking for spares. Read more

The cases are machined from steel billets, and all components manufactured to exacting specifications from high grade materials. On the road tests have proven that the bevel gear and plate pack are capable of absorbing 230lh ft of torque in front wheel drive applications. The cross pins are much more substantial than other types. Read more

Many people are wondering why Heritage can produce all the original parts for MGB and Midgets yet leave Mini owners desperate for such major panel work as Mini doors or door skins, as fitted to every Mini saloon up to 1969 and all vans. It is getting serious now as the front panel and rear valance for the van is also obsolete. The major difference between Mini and MG is the fact that the MG was stopped in production... Read more