The crux of the problem is the suggestion that fitting Hi-Los (or some such) will afford you the convenience of winching the ride height up when carrying a larger than normal load

I have been fielding a lot of questions re raising and lowering Minis, mainly from our foreign brethren. The increase in exported Minis to farther shores has revitalized interest in our precious Mini, indeed some new owners have rarely seen one of them and are delighted by it's 'cutesy' character, unbelievable road-holding and the discovery of the plethora of (relatively) cheap, readily available spares and accessories.

One of the first 'tuning tweaks' applied is dumping the car in the weeds. The Internet has also played its part in increasing interest in the Mini. It also provides near-direct links from the beginner ('newbie') or first time owner with those who have extensive knowledge and experience in dealing with our favourite little car. Read more

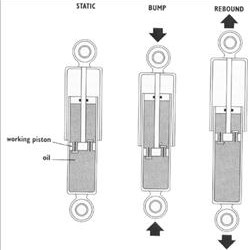

The damper's job is very simple to explain - to keep the tyre in contact with the ground wherever and whenever possible... Read more

Practically every Mini owner can name the brilliant engineer responsible for our obsession. Many can name the man responsible for the rubber suspension spring.

A goodly number know a fair bit about the engine's heritage and the man who came up with the extremely efficient cylinder head design.They account for the biggest chunks of the Mini's anatomy. But what about that other extremely simple yet hugely effective instrument that features so prominently when engine tuning occurs - the SU carburetter? A limited few can tell you what 'SU' stands for, extremely few have any idea of its concept and evolution. So let's put that right… In the beginning Strangely enough, it all started way back with William Banks Skinner; one of the owners/directors of the well-known Lilly and Skinner footwear distributors.

Read moreSince there is already a very good source of starting points/applications for fixed needle carbs, this is for those floundering about in the wilderness that is the biased (swinging) needle example of the breed.

Unfortunately I cannot give an all-encompassing table of what needles are needed for which engine builds. My life's collection of all the automotive-orientated work I'd ever done was stolen out of my car by some low-life scum a few years back. Not for what it was - but for what it might be. All I have is a few scribbled notes, the source of where I start now. Being an oft-voiced question on the message board, I thought I'd share it with you. Since there is already a very good source of starting points/applications for fixed needle carbs, this is for those floundering about in the wilderness that is the biased (swinging) needle example of the breed. Read more

Something that crops up when any modifications are made to an engine - mainly in the form of improving induction and exhaust capability - is that of idle quality.

After applying aforementioned freer-breathing products to enhance power output, many complain that no matter what - including post rolling-road tuning - they can not get a satisfactory, steady idle setting. And this after checking for manifold/gasket air leaks and spindle to carb body play (usual suspect as the spindle wears quite dramatically over several thousand miles). There is one thing that is often over-looked - the air valve found on many later model cars. This sprung-loaded air valve is built into the butterfly, sometimes called a 'poppet' valve or anti-dive valve. It is primarily there to reduce emissions when the engine is on the over-run - closed throttle at speed, i.e. anything other than at idle and gearbox in neutral. Read more

Basic knowledge Even though the SU carburetter (carb) is a very basic yet precise instrument, some fundamental understanding on just how it works is needed to be able to deal with common problems and tuning. Following is as basic a description of what's going on that I can manage! First you need to be comfortable with the main aim of any carb - to supply the engine with a finely atomized fuel/air mixture in the right strength for all operating conditions. This means from idle to flat out and everything in-between. All carbs achieve this using the same method - a venturi or choke (restriction) is used to speed up the velocity of the in-coming air to create a reduction in pressure. This is used to draw fuel from the float chamber via a suitably sized jet hole into the air stream, and hence into the engine. The perfect carb will supply the engine with optimum mixture for both maximum power throughout the full throttle-angle range (variable restriction - as in butterfly and spindle) and minimum consumption under all part-throttle conditions. Read more

Modern technology continually sweeps its ever-growing arm across all manufactured products and the SU was no exception. From closer scrutiny, and more demanding emissions control the HIF variant was born. So what have they done to improve it over its predecessor - the HS - and is it worth hanging out for? PROS. Integral float - the 'IF' in the new type number HIF. The previous H and HS type carbs with their side-mounted remote float bowls worked fine until used in racing where serious cornering speeds generated enough G-forces to lean-out the fuel mixture. The remedy was to fit a spacer between the float lid and float bowl to raise the fuel level held in it. OK when running, but at idle and rest, fuel would bubble out of the jet - causing bore washing, poor pick-up, and horrendously rich CO mixtures at idle! Fitting the float integral with the carb, directly below the jet hole (port/orifice), eliminated this problem. Jet temperature compensation - This was first aired on HS types, and was known as the 'Wax-stat' type. Read more

On some HIF carbs, the vac take-off sighted just after the butterfly - that's between the butterfly and the carb to manifold mounting flange - has been eliminated. Instead, the engines these carbs are fitted to use a vac take off in the manifold. The reason for this is again wholly idle emissions orientated. The higher vacuum that exists in the manifold area can be used to pull more ignition advance. Theoretically this will reduce emissions at idle. Unfortunately it's exposed to induction pulsing. In the A-series, this is UGLY. The pulsing and high manifold vacuum causes rough idling. Particularly where anything 'sportier' (ANYTHING) than a bog-stock-standard cam profile is used.

Classic example - the MG Metro. Its adventurously sporty cam makes for a slightly lumpy idle. This increases idle speed emissions, so Rover use manifold-sourced vacuum to increase idle speed ignition timing via the vac advance. Read more

This subject is a regular message-board poser. Many of us have touted our preferences and discoveries whilst playing about over the years.

One problem with trying to deal with it on the message board is the sheer volume of information offered and available against the time availab

Classic example - the MG Metro. Its adventurously sporty cam makes for a slightly lumpy idle. This increases idle speed emissions, so Rover use manifold-sourced vacuum to increase idle speed ignition timing via the vac advance. It is a little on the thin side, but the whole engine tuning data for each engine is based on using this oil. Used as such it works very well, especially where economy is the main goal and the car is driven very sympathetically.

ATF - 'automatic transmission fluid'. A very good substitute where the genuine SU dashpot oil isn't available for use in STANDARD spec engines. Read more

Although there are a number of different versions of the HIF type carb, they all essentially share the same type of connection layout.

The diagram below depicts the most common type - the connections can be on either the right hand side (as illustrated below) or the left hand side. Some have the connections shared on either side. Whichever, the port functions are the same. It isn't essential the crankcase breather pipe be connected - you really don't want that choking crap from the crankcase spoiling your nice, fresh, fuel-rich incoming mixture - but it's obviously essential to block the port off if you don't. A blob of RTV Silicone is sufficient in most cases. To adjuster mixture - screw the adjuster in to richen, out to weaken. There may be a 'anti-tampering' cap in there on some carbs - just hook it out.

Read moreFor some reason, I have recently had a spate of queries about this stuff. So I thought I'd do a quick tech thing on it, seeing as most of the little available information is seemingly misleading.

'Into the valley of death, rode the six hundred.........' No, this isn't about silicone microchips, or anything about computers at all. Having just done that stuff on disc brakes, it prompted me into thinking about the braking systems as a whole, one thing lead to another, and, well, and brake fluid. More exactly, silicone based brake fluid. For some reason, I have recently had a spate of queries about this stuff. So I thought I'd do a quick tech thing on it, seeing as most of the little available information is seemingly misleading. Silicone based brake fluid has been heralded by some as being the last word in brake fluid, yet also brings a look of horror onto the faces of some. Strange, eh? Read more

A fairly crucial part of how the primary gear operates is its tolerances and running clearances. End float is a continual problem as folk either ignore it through ignorance or lack of accessible information on how to do it, or belief special tools are needed.

Terminology: DTI - Dial Test Indicator Also, later factory assembled engine units (from about 1992 onwards) were built up using whatever thrust washers were available, since Rover were not making regular orders for all shim/washer sizes due to the forthcoming end of production. Consequently, many units left Rover with incorrect (usually too big) clearances. The primary gear was no exception. Too much end float and clutch disengagement is adversely affected, the gear floating up and down the crankshaft in unison with the clutch plate. The result is a graunching gear change since the plate isn't clearing the flywheel and pressure plate surfaces fully. Too little end float and the gear is likely to be pinched tight as it gets hotter in operation. Read more

Although not of immediate interest to many road-runners/street-burners, mainly accorded to the racing scene, it seems to be a perplexing problem to a very large number of folk around the world, and has burned up plenty of telephone time. Distilling the myriad of 'the symptoms go like this' descriptions down from various languages it has been put to me in - the end result was always the same. The bushes at one end or other, and sometimes both, had failed in their duties. Incidentally - some of the confusion when trying to sort the problem descriptions was down to misunderstandings about which end of the primary gear is which. To put the record straight, the end nearest the engine is the FRONT end. Consequently the end nearest the flywheel is then the REAR end. The two biggest outstanding symptoms were severe oil leaks onto the flywheel/clutch assembly, and difficulty/impossibility in selecting gears. Read more

This is going to be REAL short!

There's only one. No choice in the matter as it comes attached to the diaphragm.

Game over.

Read moreApart from very first one that should be avoided at all costs (cast in part no.2A3509), there is an astonishing five other types generally available. For high-tech ones see 'Flywheels & Pressure plates - technical advances'.

22A598 - Number cast in. Standard-grade cast iron

22G270 - Number cast in. High-grade cast SG iron as fitted to Coopers and Cooper Ss Quinton Hazel - Triangular in shape, but only standard-grade cast iron.

C-AHT230 - Mini Spares high-grade SG cast iron, but cast pre-lightened. Farndon Engineering - Machined from steel billet.

The first two can be lightened, see accompanying diagram. Limit removal of metal on the rear face to 0.120" to be safe, 0.150" if you're feeling brave/lucky. Read more

For many, trying to make an informed decision about which type of pistons they should use for their application is a very difficult thing to do. Mostly you have to rely on guidance from a very few sources such as engine builders and Mini spares specialists, who are most likely to recommend whatever it is they use or sell.

And that is not necessarily a bad thing where those companies have strong reputations for good quality products. But even those specialists may not know all that much about the pistons they use or sell. Particularly since trying to get any really useful information out of the manufacturers concerned is practically impossible. Try contacting AE Hepolite technical. Getting hold of someone takes real perseverance. Having achieved that meagre goal, enquiring about piston specification gets those ‘lemon sucking’ sorts of noises – anybody would think you are asking for the Holy Grail! So I’m going to try and cut through the techno-babble to help you identify and know what is what. Read more

Under 'Pistons - Favourable features for maximum performance' it would seem that the Mega pistons fit the bill just about spot on for all but perhaps the most extreme of racing engines. Or are they? Having used these pistons in all sizes from +0.020" to 73.5mm in all aspects of use - road/street to full race I am now in a position to give a report on their performance. Some have reservations about using the pistons in racing engines because they are a few grams heavier than other pistons available, and they are cast as opposed to forged. However, Mini Spares recruited the AE Hepolite Group for their unquestionable and renowned design and manufacturing expertise. The goal was to produce the most robust piston possible given reasonable cost and weight limits. Applying current technological advances incorporating their very latest hi-spec AE109TF lightweight alloy and special double heat treatments, the result is an extremely durable piston that will withstand greater cylinder pressures at higher rpm than any other currently available. Read more

The over-riding factor that influences just what is best for an A-Series engine is the block's propensity for flex at higher rpm, and the crank's equal propensity for flex at the same sort of rpm levels. Both combine to require a piston that is as stable as possible to maintain effective and consistent ring-seal performance. Reduced ring seal equals dramatically reduced performance. And none of this is at all helped by the relatively enormous distance from the wrist pin centre to crown height on most A-series pistons. Overall shape For the longest time, pistons were made round (well, 'ish' anyway) and straight sided (again - 'ish' is applicable here too) to form a cylinder, the top closed in to retain the all-important fuel/mixture charge; mainly because this was the simplest shape that would fill/block off the cylinder (bore) in an engine to greatest effect for minimum outlay. Read more

Throughout my admittedly fairly short journalistic career writing for the specialist Mini magazines I've tried my very best to enlighten as many of you as possible about the most common topics put forward by others, but within a magazine there's always limited space and there's always the desire for more.

Read moreThe correct running temperature of the oil is perhaps even more important than the water/coolant temperatures - so let us consider how to control them.

Mainly because it seems to be the most misunderstood of the whole process, and oil cooler fitment almost a reflex when over-heating occurs where a tuned engine of any type is concerned. And in many cases on standard production road cars for that matter.

Almost since the appearance of the immortal Cooper S, fitting an oil cooler has been the essential thing to do to any tuned Mini without any comprehension why. The original fitment was necessary because oil and bearing technology wasn't too advanced. Asking an oil of yester-year to cope with lubricating an engine at racing speeds, and a gearbox pushed their performance to the edge of their all too narrow capability, so extreme control over their working environment was essential for reliability. Hence oil cooler fitment.

Read more