It's criminal. Folk spend fortunes putting together super-sonic motors, only to skimp on the oil they use. Why? Oil's oil right? Wrong. Even if it's a standard engine, it deserves TLC considering it's extremely hostile working environment.

Oil is literally the engine's life-blood. The opening few sentences are astonishingly true. Oil isn't there just to prevent all metal components within an engine fusing together in the first few seconds of running, creating a total melt down of Chernobyl proportions. It's an intricate blending of chemicals to protect the engine as a whole.

The most commonly uttered statement about engine wear is most wear occurs within the first 10 minutes from start up when cold. True if cheap chip fat oil is used.In performance and race engines, a considerable amount of wear is created by heat, load, speed, and pressure. Again, cheapy oil won't give protection here. Read more

Essential to the well being of every engine is its oil pump and oil. Much in the same way as the heart and blood is deemed relatively important to us humans! It's also another of those greatly misunderstood and, unfortunately, misrepresented subjects connected to engines.

An alarming number of so-called A-series engine specialists would have you believe that once parting with a veritable bundle of your hard earned readies on that mega motor, what you really need to keep it in good health is a high-pressure/high-flow oil pump. Seems a sensible consideration - except in the A-series world it's impossible. Oh, there are pumps that will give better flow rates than others, but high pressure? Absolutely not.

Oil pressure is regulated by the relief valve in the block of an A-series, not in the oil pump as with say a Ford. Yeah, you know - the one that gets jammed, causing heart failure as you believe your crank bearings have dissolved, and is a pig to get out. Read more

Here's something unusual that cropped up a little while ago that I've never commented on before - main oil gallery plugs/bungs.

I'd been conversing via e-mail with a guy that was experiencing weird oil flow/supply problems with his performance street engine. Initially he'd been blaming it on the supposedly superior oil pump he'd bought. He sent it to me; I inspected it and found it to be in perfect health with no signs of causing the issues in hand. Firstly there was a claimed total oil drain down from the pump causing lack of initial supply on start-up for a few seconds, and then repeated crank bearing failures when used in anger (i.e. at high rpm for protracted periods). Unless there is something drastically wrong with the oil pump and fitment - cracked pump body, non-flat mounting surface, mounting bolts too long, split gasket, etc. - it will not drain down simply because the inlet and outlet ports are above the centerline, near the top of the pump as it is mounted to the block. Read more

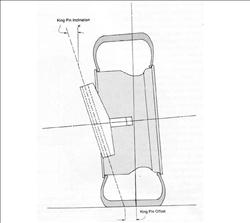

King Pin Inclination (KPI) - the angle is described by a line drawn down through the top and bottom ball-joint (swivel pin) centres and vertical viewed from the front. Extended to ground level, the distance from here to the wheel/tyre... Read more

OK, so what's happened to the Min Tec/Mini Spares development program?

It has been a long time between my first few words on basic injection car tuning and these - for that I apologise, but business has been unbelievably fraught this year.

I did promise regular and frequent up-dates, but the best laid plans, and all that… As I said, business has been more than brisk.

OK, so what's happened to the Min Tec/Mini Spares development program? Apart from a whole lot of investigation and repetitive research into what's available currently - not that much. It is all hinging on this forthcoming ECU from this particular company. Unfortunately the company concerned is not run by businessman or automotive engineers. They are electronics whiz kids who are trying to achieve the Holy Grail. Read more

Modern technology has seen dramatic improvements in power outputs over very recent years. Just look at Formula One, where 3000cc engines are now putting out the sort of power not even dreamed of not so long ago at rpm levels that make motorcycle engines flinch!

At the end of every racing season the new/recurrent champions are confirmed, and the rest of the field turning their attention towards next year/season and ways of beating the crowned champ. Invariably this involves that age-old quest for the illusive extra horsepower this year's champion seemed to have over everybody else. So I thought it may be useful to have a look at some stuff that is largely over-looked by many and to further agitate those little grey cells.

Modern technology has seen dramatic improvements in power outputs over very recent years. Read more

Firstly - re-runs or re-hashes of technical literary prose always brings to light either new, or old forgotten subjects for close scrutiny/re-examination. The arrival of 'A Well Known A-Series Tuning Bible' is no exception. Good news as far as I'm concerned as it keeps me gainfully employed!

This dissertation is centred upon that old chestnut 'ignition systems'. Technological advances running through the entire automotive world hasn't ignored the system that supplies life-giving sparks to bring your engine alive. It's true - no spark, no power. Much of the technology applied has been about making bigger, fatter, longer lasting, and more consistent sparks. The plethora of Mini spares suppliers have embraced this whole-heartedly as it's another string to their bows of profit generation. And it's this that's causing the problem - again Mini owners are being sold stuff that they don't need, or more pointedly will NOT increase power out-puts one iota. Read more

Something that came to light during a conversation with a colleague and friend may be worth passing along.

It's one of those things that, once ingested, lurks in the dark corners of the mind until a pertinent situation comes along. Such a situation reared its head a couple of weeks back - so now's the time to spread the word before it disappears back into obscurity.

Engine's that run on or pink (detonate) for some seemingly illusive reason may well be suffering from a problem that causes an apparently correctly chosen heat range spark plug to run too hot. The problem is worn spark plug threads in the head. This reduces the heat-path required to cool the plug, consequently it over-heats and causes the aforementioned problems. So if you come across this one, check the plugs for fit in their threads. If they're loose, try the next heat range up!

Read moreI have been using the Ignitor ignition systems for some 8 years or so, as long as they have available in the UK, and have never found fault with them nor had any reliability issues. Until the beginning of this year… A new customer for this year, racing an MG Midget here in UK under a limited mods category, was doing splendidly for the first couple of races, then started experiencing a misfire. Initially it was believed to be a fuel starvation/vaporization issue. All fuel pipes were checked and re-routed where it was considered necessary. Those still considered in danger of getting too warm were heat shielded. The misfire persisted. On to the ignition system. All was checked, but then a loose alternator wire was found and blamed for the fault. It wasn't. Back to the ignition system then. Read more

Establishing an accurate TDC reference point is of paramount importance when developing and monitoring ignition timing (and cam timing come to that). Terminology - TDC - Top Dead Centre BTDC - Before Top Dead Centre Establishing an accurate TDC reference point is of paramount importance when developing and monitoring ignition timing (and cam timing come to that). When an experienced engine builder assembles an engine - no matter whether for road or race - he will establish an accurate TDC indicator that can be used for ignition purposes. Usually contrived as a rigid pointer aligning to a corresponding mark on the crank pulley in a position easy to see with the engine installed. Unfortunately, many of us have to deal with engines that haven't had such attention to detail - so either have to make do with the standard ignition timing graduated scale if it's there or sort something else out. Read more

I'd like a pound coin for every time I've been asked about what these are all about and why they are used. Folk seem to hold them in some kind of awe - but they are very simple. The ballast resisted ignition system was - I believe - developed by Ford when they were experiencing poor starting on a certain prodigiously-used 4-cylinder engine. To get round the issue of the massive current drain caused by the starter motor functioning, the ballast-resisted system was designed. When you hit the starter button/key, a massive drop in available current to the coil occurs as the starter motor does its thing. The colder the weather or the more worn the starter motor, the more current it draws, the less there is passed to the coil to instigate ignition. Read more

Calculation for gear ratios and transmitted engine rpm Basic rule to remember is ratio is established by dividing tooth count on driven gear by the tooth count on its driver.

Basic rule to remember is ratio is established by dividing tooth count ondriven gear by the tooth count on its driver. To work out overall gearbox ratios you also have to establish the constant ratio.

Terminology -

FD - Final Drive (diff ratio)

Calculation for establishing vehicle speed for different final drives.

Formula : 60,000

FD (Final drive/diff ratio) x wheel rev per mile.

The fuel situation seems to be worsening at a great pace these days. And as is exhibited by the questions that appear on the message board many folk are confused by what they can and can't do, and what is best to do as far as race engines go.

Many have posted (particularly from the States) that nothing need be done - just run on unleaded. They've been doing this for years and never had any problems. I have trouble believing that in the face of what I know and have investigated - so here's what the score really is.

Years ago this stuff called Tetraethyl lead was originally conceived as an octane enhancer. It was soon discovered, however, that the metallic oxides produced by the combustion process formed a protective coating on the valves and seats. This coating prevented micro welding of the valve seat to the corresponding seat in the head under high temperature operation.

Read moreIf there's one subject that gets washed over when transplants or modifications are discussed its the flywheel and clutch assembly. There also seems to be a widely held belief that up-rating an engine from anything other than standard automatically requires a 'competition clutch'.

This, as with many other subjects concerning the Mini, is a myth. May be it's because the prospective transplantee needs not only a bigger/more powerful engine to amaze folk with in the bar stool bullsh*t stakes, but also anything that can be dubbed with the word 'competition'. 'Up-rated', after all, is a fairly tame word.

Although many have written much about how to modify engines, some suspension, and even on bodywork, very little has been written about the flywheel and clutch. Bit strange as it's an essential part of transferring engine power to the wheels! So let us delve into the myths and legends concerning this enigma of power transfer. Read more

There is only one version of this flywheel as standard, and fits all A+, Verto or Valeo (same type, different manufacturer) installations. And it's heavy. Very heavy.

Those up-rating power outputs in later Minis bearing this set-up were stuck with it. It is possible to shave a few ounces off this chunk of iron, but is difficult - especially for the DIY-er - and not cost effective when paying to have it done. Mini Spares recognised this shortfall early on. Sympathising with the plight of their customers, they produced a replacement outer section for the Verto kit from the same high-grade steel as used in the other light-weight versions.

| LB | KG | |

| Standard Verto flywheel outer section only - unmodified | 12.83 | 5.82 |

| Steel Verto flywheel outer section only | 8.84 | 4.01 |

The advent of ECU-equipped fuel injection saw the need for a trigger system to provide the ECU with information on engine speed and piston position. In their infinite wisdom, Rover decided to fit a reluctor ring into the rear of the already humungous iron flywheel section.

Identical in all aspects to the non-injection flywheel except for this reluctor ring and the raised ridge it is fitted into. It weighs a little more than the non-injection item, but can be fitted to non-injection pre-engaged starter endowed cars should the situation deem it necessary. But ONLY the flywheel - NOT the diaphragm (see 'Pressure plate - Verto types' for further details). Consequently the same in-effective non-cost effective limited lightening can be carried out to the standard item.

Identical in all aspects to the non-injection flywheel except for this reluctor ring and the raised ridge it is fitted into. Read more

Now I just know I'm going to make myself very unpopular with an array of people by doing this article, but I can't help myself. It is something that plagues me continually.

It does not seem to matter which way I try and explain it, or how I represent it, I always meet a barrage of either unsubstantiated or uneducated reason and arguments. So now I have the stage to myself, I will put this as I see it from a wealth of experiment and reasoning over the past twenty years or so.

Exhausts. A subject that a great deal is known about in theory, yet a diminutive amount is actually applied in practice as far as the poor little A series engine is concerned. In fact, the only country where I have seen any money/time put into developing exhaust systems (and that means from cylinder head to the tailpipe) for the venerable little motor, is in America. It is a consequence of those that race and seek the ultimate fully expect to have to pay for it. Read more

The recent rolling road re-test of the 1275 engine build I did saw an opportunity to do some exhaust systems testing.

I had noticed a few years back that the RC40 was being manufactured by a different process than the originals - giving rise to a change in the shape of the bends applied to the system. I had wondered if they would be causing a restriction at all - but hadn't had the opportunity to test it. The lack of expected power from the aforementioned engine lead me to investigate all possible angles from the tyre contact patch to the carb mouth. I found nothing that explained the 14 or so bhp I was 'missing'. After some application of the old grey cells I mentally narrowed cause down to one of two things - either the piston oil control rings were still causing excessive drag (75% of all internal friction of an engine is generated by the piston rings) or perhaps these new bends in the venerable RC40 were indeed causing a power loss.

Read moreStandard cast iron manifolds

Pic 1.

Standard cast iron manifolds - Mini on left, Metro ‘LCB’ type right. One major benefit of cast iron is noise absorption. Tubular steel amplifies resonance caused by exhaust gas phenomena. Stainless steel being THE worst.

Pic 2.

Cooper Freeflow. Careful, exquisite forming of primary pipes and neat welding ensures un-interrupted flow of exhaust gases. Medium length primaries promote performance where mild cams are used.

Pic 3.

Ubiquitous LCB. The two outer ports are connected by short primaries joined to a larger secondary pipe, the centre port getting one pipe all to it’s self. These equally sized pipes continue down under the car, ending in a ‘Y’ piece to join them to the system.

'The third stroke, that following the compression stroke,of our four-stroke Mini engine’s the only one producing power. The other three consume it. Here we’re looking at with exhaust manifolds, so what we need to consider is how to minimise power consumed on the exhaust stroke as the piston pushes the spent gases out.

Recap

Terminology-

LCB -Long centre Branch

A free-flowing set up’s the name of the game - size playing an important role. It’s always assumed a bigger bore pipe will flow better than a small one, so there’s a tendency to follow the ‘biggest is best’ principle and go for the biggest that can feasibly be fitted. Unfortunately it simply doesn’t work, as this generalised and simple view doesn’t consider the phenomena taking place within an exhaust system.

Read more