This large plastic shield was Rovers last attempt to cover the engine electrics on all minis except for MPI cars 1996 on. It might need slight modifications by narrowing for some SPI cars but they have been fitted to many cars without any problems. Read more

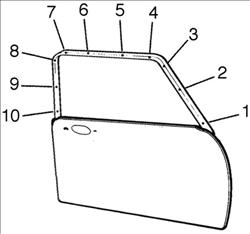

10 fixings per trim – Evenly spaced along each straight section.

Not on the curved parts (corners)

Numbers 1 & 10 are slide on, all the others are pop on type.

The holes are drilled 1/8” Read more

10 fixings per trim – Evenly spaced along each straight section.

Not on the curved parts (corners)

Numbers 1 & 10 are slide on, all the others are pop on type.

The holes are drilled 1/8” Read more

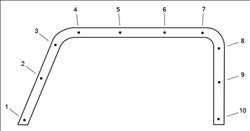

Vertical rear moulding for the Estate and Traveller rear side windows.

With the double row channel grooves facing upwards. This is a side view elevation.

This channel will require the ends to be cut exactly as above to the original angle of 20 degrees and the correct length as shown which ensures the best fitment. As the material is not the easiest to cut cleanly it is recommended that a new hacksaw blade or good quality snips are used and the channel grooves are packed with wood splints.

Alternatively, you can use your old original sample as a template. Read more

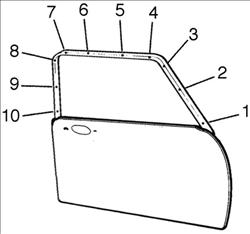

For any high performance engine an efficient crank damper puller is essential to minimise potential failure caused by harmonic vibration generated by the crank assembly. The standard type damper is barely adequate for the standard engine in normal everyday use. When used on up-rated engines to ANY degree, it has severe short-comings.

Read more

We now have a new range of electronic ignition distributors available. Read more

These downloadable templates can be printed out to scale to help you fit the sportspack for: - MS135 - WHEEL ARCH SET OF 4 GENUINE SPORTSPACK ARCHES Read more

The cable bracket is made to fit universally and will replace the original bracket as tacked in on the latest Minis. The funny looking tag, which points to the heater, is used on later cars to hold a relay and the single bolthole faces the front. This bracket should be fitted about 3" back from the lower padded rail of the parcel shelf and 5-6" from the R/H door seal. Ensure the choice of bolt holes in the cable bracket lines up with metal on the parcel shelf as latest vehicles have gaps (visible from underneath) and the plastic cloth of the parcel shelf would tear. Read more

Every effort has been made in the production of this pin to ensure its maximum specification with regard to material, heat treatment, and finish ground size.

The planet wheels to be used should be checked on the pin prior to assembly to ensure a reasonable tolerance. If excessive play is evident, select different planet wheels.

Due to excessive manufacturing tolerances, it should not be assumed that new planet wheels will be okay. Selection by trial and fit should be employed. If intended for arduous use Minispares recommend using the Molybdenum coated pin C-BTA164.

Use of high detergent content engine oil will drastically...

Read more

To enable use of these centre main straps, the centre main cap has to be machined flat to the nearest cut, to level the cap between the main cap bolt holes horizontal surfaces.

To achieve maximum thrust washer location, it is possible to machine the cap down its centre section using a one inch...

Read more

We have just released our brand new 8.4" calipers, that were original fitment to later 1275 Gt's and all Mini's after 1980

Having not been available new for several years, Minispares have stepped in and had these remanufactured from new castings...

Order as part number 37H8128 for R/H

Order as part number 37H8129 for L/H Read more

Manufactured from high-tensile manganese-bronze, these baulk rings were developed for competition use where the standard sintered metal baulk rings have proven far from adequate. This material is not to be confused with the brass/silicone- brass materials, all-over-machined, experimented unsuccessfully with by others in the late eighties/early nineties. It is a purpose-sourced material, precision cast and finished-machined using the very latest technology.... Read more

With the engine and new 5 speed transmission re-installed in the vehicle, the new gear selector parts must be fitted before re-connecting the gear selector extension shaft. The new selector parts can be assembled without removing the gearchange remote from the vehicle. It is recommended that the gear lever be removed.... Read more

Your 5 speed gearbox has a special 5th gear, laygear, and reverse idler shaft assembled with a modified gearbox main case and a different speedo end casting.

These parts must be removed before the main gearbox cluster can be removed. When a clean work area has been prepared, the removal of the 5th gear and laygear is as follows.

1. Remove the new speedo end casting assembly with the two bearings. These are a slide fit in the casting and are not positively retained.

2. Remove taper bearing No LM11749 off the 5th gear shaft along with the needle roller bearing carrier from the bore of the 5th gear, leaving the gear loose on the shaft.

3. Remove diff and housing as per workshop manual, turn the selector rod at base of diff housing area anti clockwise-and with the spool pull out as far as possible... Read more

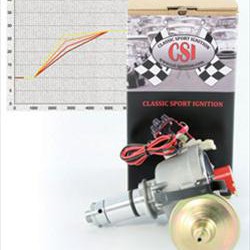

10 fixings per trim.

Evenly spaced along each straight section. Not on the curved parts.

Nos 1&10 are slide on, all others are the pop on type the holes are drilled 1/8"

Read more

The bias barrel was originally developed as part of our five speed gearbox package, necessary to facilitate accurate gear selection and gear lever position.

It soon became apparent that this device would vastly improve the gear change on the standard four speed rod change gearbox, endowing Minis and Metros with the ‘modern car’ feel, and taking the quessology out of gear selection.

Read more

Still produced from the original tooling purchased in 1990 from Jim Whitehouse these Arden alloy 8 port heads were never a straight bolt on conversion. Designed with racing in mind it was developed in 1966/7 to take full advantage of the change to Group 2 racing regulations which allowed more freedom in cylinder head design. Read more

I frequently hear the phrase "big-bore engines tend to be unreliable long-term because of head gasket problems". Which is complete rubbish, even when non-Payen head gaskets are used.

These big-bore engines can be supremely reliable - providing the are machined and built correctly in the first place. Something that continually astonishes me doesn't happen even when engines are built by some of the self-proclaimed A-series 'experts'.

Read more